Materials for Wall Display Cabinets: Durability Guide

Understanding Durability in Wall Display Cabinet Materials

Defining Material Durability and Longevity in Wall Display Cabinet Construction

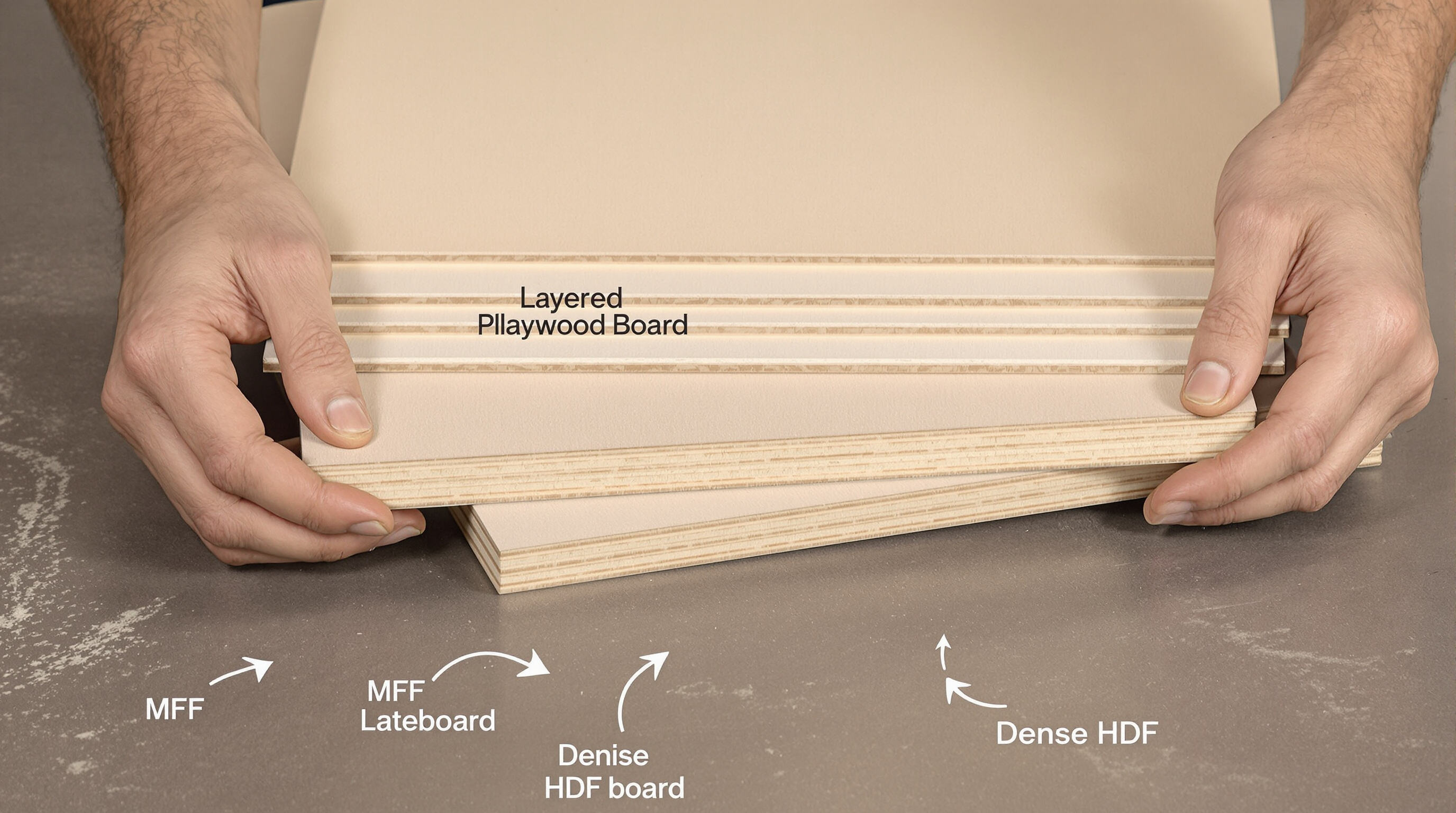

When we talk about durability in wall display cabinets, what we really mean is how well materials stand up against things like warping, getting scratched up, and taking on moisture damage without falling apart after years of use. Some top performers in this category include marine grade plywood that has been coated with waterproof treatments, plus those aluminum framed composite panels that just seem to handle humidity better than most other materials out there. For solid wood options like oak, folks need to apply proper protective finishes if they want to avoid cracks forming when temperatures and humidity levels fluctuate. Then there are engineered boards such as HDF with melamine surfaces. These boards actually have multiple layers which gives them good stability and makes them pretty resistant to scratches too. That's why many businesses choose these materials for their commercial spaces where people will be accessing displays frequently throughout the day.

Key Factors Influencing the Durability of Wall Display Cabinet Materials

Four critical factors determine long-term performance:

- Material composition: Engineered woods offer superior humidity resistance compared to natural alternatives.

- Protective treatments: UV-resistant laminates help prevent fading in sun-exposed areas.

- Load capacity: Steel-reinforced frames can support over 50 lbs per shelf without sagging.

- Environmental exposure: In coastal regions, materials must provide triple the corrosion resistance of standard options to withstand salt-laden air.

| Material | Moisture Resistance | Scratch Resistance | Max Load Capacity |

|---|---|---|---|

| Marine-Grade Ply | ★★★★★ | ★★★☆☆ | 75 lbs |

| Powder-Coated Steel | ★★★★☆ | ★★★★★ | 150 lbs |

| Thermofoil MDF | ★★★★☆ | ★★★★☆ | 40 lbs |

How Build Quality and Installation Affect Long-Term Performance

The best materials still won't perform well if they aren't installed correctly. Take wall display cabinets for instance - these need those heavy duty commercial anchors when placed in areas with lots of foot traffic or machinery vibrations. A recent study looking at architectural hardware found that units not properly secured tend to give out about three times quicker because of all that constant movement wearing down the mount points over time. When it comes to shelving, going for designs that include built-in anti sag supports along with traditional mortise and tenon joints makes a huge difference. These setups cut down on structural failures by around two thirds compared to just using simple brackets. The result? Shelves stay aligned much longer and can hold heavier loads without warping or collapsing after months of use.

Solid Wood vs. Engineered Wood: Long-Term Performance in Wall Display Cabinets

Strengths and weaknesses of natural wood for wall display cabinet applications

Wood still stands out as one of the best options around because nobody can beat its natural look and solid build quality. Hardwoods such as oak and maple really hold up against knocks and bumps, often lasting half a century if someone takes good care of them. The way these woods have their own special grain patterns gives any space a warm feeling that plastic or composite alternatives just cant match no matter how hard they try. But there is a catch worth mentioning here. Solid wood does react to changes in humidity levels, which means it might warp or cause gaps between boards when exposed to different climate conditions. Some people actually like the aged look that develops over time, but regular sealing becomes pretty much mandatory for keeping everything stable dimensionally and stopping water from getting into the wood where it doesn't belong.

Engineered wood vs. solid wood: Durability, warping resistance, and structural stability

Wall display cabinets made from engineered wood tend to hold their shape better in spaces where humidity levels fluctuate quite a bit. The secret lies in how plywood and MDF are constructed with these layered cores running in different directions. This cross-grain arrangement basically fights against the natural stresses that would otherwise cause things to warp or twist out of alignment as seasons change. Sure, solid wood can take on heavy loads just fine, but it doesn't handle shifting conditions nearly as well. Anyone who's dealt with doors sticking during winter knows what I mean. According to recent findings from material science studies conducted last year, there are some pretty notable distinctions between these options when looking at long term performance metrics.

| Performance Factor | Engineered Wood | Solid Wood |

|---|---|---|

| Humidity Resistance | High | Moderate-Low |

| Warping Potential | Reduced by 60-70% | Grain-dependent |

| Structural Consistency | Uniform cross-layering | Variable natural grains |

This makes engineered substrates better suited for installations where climate control is inconsistent.

Best wood types and protective finishes for moisture and scratch resistance

Choosing the right wood species and finishes significantly extends cabinet lifespan. For solid wood:

- Hardwood choices: Quarter-sawn white oak resists moisture penetration; closed-grain maple provides superior scratch resistance

- Protective coatings: Catalyzed conversion varnish creates a nearly impenetrable moisture barrier, showing an 80% lower failure rate than standard polyurethane after 1,000 hours of humidity testing

Engineered boards achieve maximum protection with phenolic resin-saturated overlays or thermo-fused acrylics–surface treatments that deliver 95% water repellency per ASTM D1037 standards. In high-traffic areas, UV-cured nano-ceramic finishes increase scratch resistance up to threefold while preserving sheen for over a decade.

Plywood, MDF, and HDF: Evaluating Structural Integrity and Surface Durability

Plywood in wall display cabinets: Layered strength and humidity resistance

The way plywood is built with layers going different directions actually makes it much more stable when dimensions are concerned. This helps prevent those annoying warps that happen when there's moisture in the air going up and down. For places near water or where humidity gets pretty high, marine grade plywood comes into play. These special boards use waterproof glue called phenolic adhesive, so they can handle environments with around 60% humidity. That makes them great choices for stores right on the coast or art galleries displaying sensitive works. The whole layered thing also lets each layer expand naturally without putting too much stress on the board itself. This means fewer surprises when temperatures change throughout the seasons, which saves headaches later on.

MDF and HDF performance under load and in variable indoor environments

When it comes to Medium Density Fiberboard (MDF) versus High Density Fiberboard (HDF), both offer pretty good stability because their particles are spread out evenly throughout the material. The moisture resistant version of MDF actually handles swelling issues much better too about 40 percent improvement when conditions change around. Speaking of HDF, this stuff packs quite a punch. With densities starting at around 900kg per cubic meter, it can hold about 30% more weight compared to regular MDF boards. Plus, screws stay put even after going through those temperature changes we all hate dealing with during construction projects. If someone wants to get the most out of their MDF products, they should probably stick to areas where humidity stays below 55%. But don't worry about occasional humidity spikes if using HDF since it can handle brief increases up to 70% without major problems.

Advanced surface coatings that enhance durability of engineered boards

The molecular barriers created by UV-cured acrylics and catalyzed conversion varnishes boost scratch resistance dramatically, somewhere around three times what we see on regular surfaces. They also stop about 95 percent of moisture from getting through, which is pretty impressive when compared to materials left unprotected. These kinds of non-porous finishes stop vapor from moving through the material, so they work great in places like busy hotels or shopping centers where foot traffic wears down everything fast. Coatings enhanced with nanotechnology have another trick up their sleeve too. They stand up against oil stains and don't break down under UV light as quickly. Lab tests that speed up the aging process show these coatings lose less than 5% of their shine even after being exposed to simulated sunlight for 15 whole years. That kind of durability makes a big difference in maintenance costs over time.

| Coating Type | Moisture Blocking | Scratch Resistance | Recommended Use Case |

|---|---|---|---|

| Catalyzed Varnish | 99% | 4H pencil hardness | High-touch museum displays |

| UV-Cured Acrylic | 95% | 5H pencil hardness | Sunlit retail installations |

| Nano-Ceramic | 99.5% | 9H pencil hardness | Healthcare/hospitality settings |

Edge sealing is essential–it doubles coating effectiveness by blocking capillary moisture paths, especially in cabinets mounted against exterior walls.

Moisture, Stain Resistance, and Real-World Performance of Cabinet Materials

Comparing moisture and stain resistance across wood, laminate, and composites

Oak and walnut woods offer decent protection against moisture but need frequent sealing treatments to avoid those pesky stains. When it comes to commercial spaces, laminates really shine compared to other wood options. Recent tests from 2023 show they can fight off about 8 out of 10 everyday spills including coffee rings and ink marks. For areas where humidity is a concern, composite materials made with phenolic resins are hard to beat. These boards barely swell at all when exposed to high humidity levels and keep looking great even after years of constant use in busy environments like restaurants or office buildings.

Performance of sealed surfaces in high-humidity and high-traffic areas

Modern polyurethane sealants extend cabinet lifespan by 5–7 years in environments with 60–80% humidity, outperforming traditional lacquers. UV-cured acrylic finishes show 40% less wear in commercial galleries and retail spaces. Key installation practices include:

- Ensuring edge banding integrity to prevent moisture ingress

- Applying continuous protective coatings on load-bearing joints

- Using surfaces at least 2 mm thick for impact resistance

Growing demand for water-resistant wall display cabinet materials in modern B2B interiors

The market for waterproof MDF cores with antimicrobial coatings has seen an impressive jump, with manufacturers noting around 62% more orders compared to last year, particularly from hospitals and hotels looking to upgrade their facilities. We're also seeing hybrid construction methods gain traction, where stainless steel forms the base but combined with wood composites that resist dampness. These setups account for nearly 40% of high-end commercial projects these days. The push towards better indoor air quality is definitely driving this change too. Building codes are getting tougher on volatile organic compounds (VOCs) and formaldehyde emissions, so specifiers have to go with safer glues and materials when outfitting spaces where people actually spend time.

| Material | Moisture Resistance | Stain Resistance | Recommended Use Case |

|---|---|---|---|

| Solid Oak | Moderate | Low | Low-traffic offices |

| High-Pressure Laminate | High | High | Museum displays |

| Phenolic Resin | Extreme | Extreme | Laboratory environments |

| Powder-Coated Steel | Extreme | High | Outdoor retail installations |

Sustainable Materials and Maintenance: Maximizing Lifespan of Wall Display Cabinets

Eco-friendly materials: Balancing sustainability with durability in cabinetry

Wall display cabinets are getting greener these days, with many manufacturers turning to sustainable materials like FSC certified wood and recycled aluminum. These alternatives perform just as well but leave a much smaller footprint on the planet. Take bamboo for instance it grows at an amazing rate about thirty times faster than regular hardwoods. And when it comes to strength, bamboo actually holds up pretty well against oak too. The numbers tell the story: bamboo has around 3,020 psi compressive strength compared to oak's 2,970 psi according to the latest Green Interiors Report from 2024. Plus bamboo naturally resists mold growth which makes it great for humid environments. Then there's recycled aluminum frames they cut down carbon emissions by nearly 93% compared to new aluminum production. What's more impressive is their load capacity these frames can hold up to 200 pounds per linear foot exactly what conventional steel can manage. That kind of performance makes them a smart choice for anyone looking to build something durable without harming the environment.

Lifecycle analysis of green cabinet materials and their long-term viability

A 10-year comparative study reveals:

| Material | Maintenance Cost | Avg. Lifespan | Recyclability |

|---|---|---|---|

| FSC-certified wood | $18/year | 40 years | 95% |

| Recycled HDPE | $12/year | 25 years | 100% |

| Bamboo composite | $15/year | 35 years | 85% |

| Standard plywood | $25/year | 20 years | 60% |

These findings show that sustainable materials often exceed traditional options in longevity and cost-efficiency over time.

Maintenance best practices to preserve appearance and structural integrity

To maximize cabinet lifespan, conduct quarterly inspections focusing on:

- Signs of humidity-induced warping (maintain indoor humidity at 40–50%)

- Reapplication of plant-based wax sealants every 18–24 months

- Shelf bracket load capacity checks for early signs of degradation

Proactive maintenance extends cabinet life by 62% compared to reactive repairs (Indoor Materials Study 2023). In high-traffic areas, cleaning with microfiber every 48 hours prevents 89% of surface abrasions on matte-finish eco-friendly materials.

FAQ Section

What are the most durable materials for wall display cabinets?

Durable materials for wall display cabinets include marine-grade plywood, aluminum composite panels, engineered woods like HDF, and powder-coated steel. These materials offer excellent resistance to moisture, warping, and scratches, making them ideal for high-traffic and high-humidity environments.

How do building quality and installation affect cabinet durability?

Proper installation with heavy-duty anchors and high-quality construction methods like built-in anti-sag supports and mortise-and-tenon joints are crucial. Improper installation can lead to structural failures and reduce the cabinet's lifespan significantly.

How can I maintain the longevity of display cabinets?

Conduct quarterly inspections, maintain indoor humidity at 40-50%, and reapply wax sealants every 18-24 months. Cleaning with a microfiber cloth every 48 hours helps prevent surface abrasions, especially in high-traffic areas.